無縫鋼管生產工藝:

①熱軋無縫鋼管主(zhu)要(yao)生產工(gong)序(xu)(△主(zhu)要(yao)檢驗工(gong)序(xu)):

管(guan)坯準備(bei)及檢(jian)查(cha)△→管(guan)坯加熱(re)(re)→穿孔→軋管(guan)→鋼管(guan)再(zai)加熱(re)(re)→定(減(jian))徑→熱(re)(re)處理△→成品管(guan)矯直→精整→檢(jian)驗△(無(wu)損、理化、臺檢(jian)) →入庫(ku)

②冷軋(拔)無縫鋼管主要生產工序:

坯料準(zhun)備→酸洗潤滑→冷(leng)軋(拔)→熱處(chu)理→矯直→精整→檢(jian)驗

一般(ban)的(de)(de)無(wu)(wu)縫鋼(gang)(gang)(gang)管(guan)(guan)(guan)的(de)(de)生產(chan)工藝可(ke)以分為冷(leng)拔與(yu)熱(re)軋(ya)兩種(zhong),冷(leng)軋(ya)無(wu)(wu)縫鋼(gang)(gang)(gang)管(guan)(guan)(guan)的(de)(de)生產(chan)流程一般(ban)要(yao)(yao)比熱(re)軋(ya)要(yao)(yao)復(fu)雜(za),管(guan)(guan)(guan)坯首先要(yao)(yao)進(jin)行(xing)三輥連軋(ya),擠壓后要(yao)(yao)進(jin)行(xing)定徑測(ce)試,如果表面(mian)(mian)沒(mei)有(you)響應裂紋后圓管(guan)(guan)(guan)要(yao)(yao)經過割(ge)機進(jin)行(xing)切(qie)割(ge),切(qie)割(ge)成(cheng)長(chang)度約一米的(de)(de)坯料。然后進(jin)入退火流程,退火要(yao)(yao)用酸(suan)性液體進(jin)行(xing)酸(suan)洗(xi)(xi),酸(suan)洗(xi)(xi)時要(yao)(yao)注意表面(mian)(mian)是否有(you)大(da)量(liang)的(de)(de)起(qi)泡(pao)產(chan)生,如果有(you)大(da)量(liang)的(de)(de)起(qi)泡(pao)產(chan)生說明鋼(gang)(gang)(gang)管(guan)(guan)(guan)的(de)(de)質量(liang)達不到相應的(de)(de)標準。外(wai)觀(guan)上冷(leng)軋(ya)無(wu)(wu)縫鋼(gang)(gang)(gang)管(guan)(guan)(guan)要(yao)(yao)短于熱(re)軋(ya)無(wu)(wu)縫鋼(gang)(gang)(gang)管(guan)(guan)(guan),冷(leng)軋(ya)無(wu)(wu)縫鋼(gang)(gang)(gang)管(guan)(guan)(guan)的(de)(de)壁厚一般(ban)比熱(re)軋(ya)無(wu)(wu)縫鋼(gang)(gang)(gang)管(guan)(guan)(guan)要(yao)(yao)小,但是表面(mian)(mian)看起(qi)來比厚壁無(wu)(wu)縫鋼(gang)(gang)(gang)管(guan)(guan)(guan)更(geng)加(jia)明亮,表面(mian)(mian)沒(mei)有(you)太多的(de)(de)粗(cu)糙(cao),口徑也沒(mei)有(you)太多的(de)(de)毛刺。

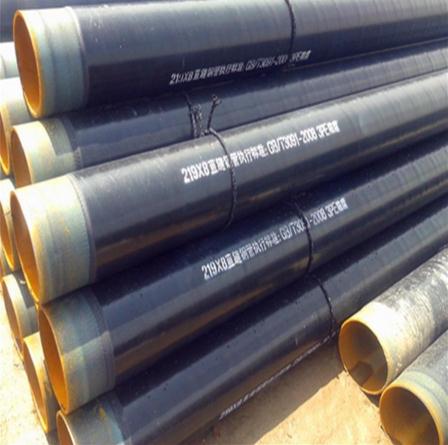

無縫鋼管分類

沿(yan)其橫截(jie)面(mian)的(de)周(zhou)邊上無接縫(feng)的(de)鋼(gang)(gang)管(guan)(guan)。根據生產方法不(bu)同分(fen)為熱軋管(guan)(guan)、冷軋管(guan)(guan)、冷拔管(guan)(guan)、擠(ji)壓管(guan)(guan)、頂管(guan)(guan)等(deng),均有各自(zi)工藝規定(ding)。材(cai)質(zhi)有普(pu)通和(he)優質(zhi)碳素結(jie)構(gou)鋼(gang)(gang)(Q215-A~Q275-A和(he)10~50號鋼(gang)(gang))、低(di)合金鋼(gang)(gang)(09MnV、16Mn等(deng))、合金鋼(gang)(gang)、不(bu)銹耐(nai)酸(suan)鋼(gang)(gang)等(deng)。按(an)用(yong)途分(fen)為一般(ban)用(yong)途的(de)(用(yong)于(yu)輸水、氣管(guan)(guan)道和(he)結(jie)構(gou)件、機械零件)和(he)專用(yong)的(de)(用(yong)于(yu)鍋爐、地質(zhi)勘探(tan)、軸承、耐(nai)酸(suan)等(deng))兩類。